The materials used in the construction of the new Corvettes have been a topic of discussion among enthusiasts. While many people are familiar with the Corvette’s long-standing use of fiberglass, there has been speculation about whether the new generation of Corvettes incorporates carbon fiber as well. In order to determine the answer, we will explore the information gathered from various sources.

Key Takeaways:

- The Corvette body materials have evolved over the years, incorporating lightweight plastics, composites, and potentially carbon fiber.

- The use of fiberglass-based composites, such as sheet-molded composite (SMC), allows for smoother panels and weight reduction.

- Carbon fiber provides advantages in terms of strength, rigidity, and further weight reduction.

- The combination of materials in Corvette construction optimizes performance, structural integrity, and occupant safety.

- As technology advances, we can expect further innovations in Corvette construction materials.

The Evolution of Corvette Body Materials

The Corvette body has evolved over the years, incorporating different materials that have played a crucial role in enhancing its performance and design. In 1968, the third generation of Corvettes introduced a new manufacturing process, utilizing fiberglass and resin in a press mold method to construct the body parts. However, a significant shift occurred in 1973 when the composition transitioned to sheet-molded composite (SMC). This advanced material consisted of a combination of fiberglass, resin, and a catalyst, forming a durable composite under high heat and pressure.

The adoption of SMC body panels brought several benefits to the Corvette’s construction. Compared to traditional fiberglass, SMC allowed for smoother panels and higher-quality paint finishes. Furthermore, the use of SMC contributed to the creation of thinner body panels, resulting in a reduction in the Corvette’s overall weight. This weight reduction played a crucial role in enhancing the vehicle’s agility and handling.

As the Corvette continued its evolution, the material composition of the body underwent further changes. While SMC has remained a vital component, the incorporation of lightweight plastic materials increased. These lightweight plastics offered advantages in terms of weight reduction while maintaining structural integrity. Additionally, the Corvette’s construction technology has advanced, enabling the utilization of a mixture of materials to optimize the vehicle’s performance.

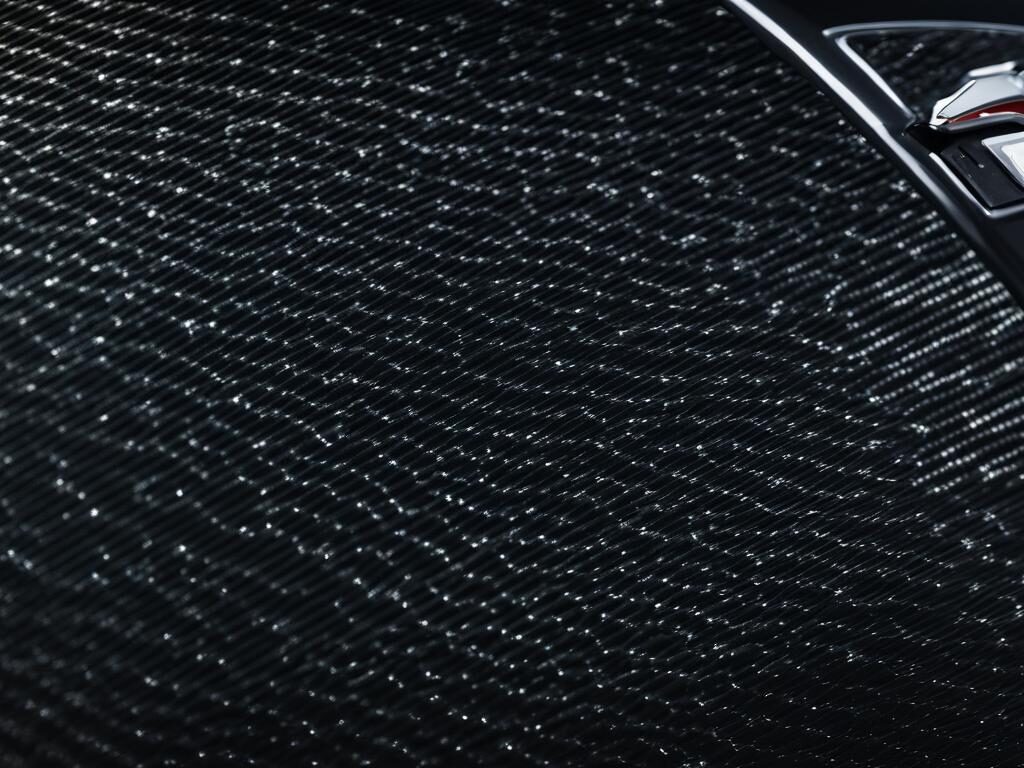

The latest generation of Corvettes may incorporate carbon fiber along with composites and plastics. Carbon fiber, known for its exceptional strength-to-weight ratio, brings added benefits to the Corvette’s body construction. By integrating carbon fiber, Corvette engineers can achieve enhanced strength, improved rigidity, and further weight reduction. These advantages contribute to the overall performance and driving experience of the Corvette.

The combination of different materials, including fiberglass, SMC, lightweight plastics, and potentially carbon fiber, in the construction of Corvette bodies demonstrates the commitment to utilizing advanced technology and adopting innovative materials. This continuous evolution ensures that each new generation of Corvettes benefits from advancements in construction techniques, resulting in improved performance, increased durability, and an unmatched driving experience.

The Role of Composites in Corvette Manufacturing

Composites play a significant role in the manufacturing of Corvettes. The Corvette’s body structure consists of a layered hybrid structure, utilizing composites, plastics, and carbon fiber. This approach not only provides lightweighting but also allows for affordable production in high volumes and the ability to produce multiple vehicle variants with low tooling investment.

The use of composites, including fiberglass-based materials such as SMC, allows for stronger and more rigid body parts, while lightweight plastic components further contribute to weight reduction.

Carbon fiber, known for its high strength-to-weight ratio, may also be incorporated into the Corvette’s body composition. These materials contribute to the Corvette’s performance, handling, and overall quality.

The layered hybrid structure of composites, plastics, and potentially carbon fiber in Corvette manufacturing enables a balance between strength and weight reduction. The utilization of composites and lightweight plastics ensures that the Corvette remains agile and responsive on the road, while providing structural integrity and durability. The inclusion of carbon fiber, with its exceptional strength-to-weight ratio, enhances the overall performance of the Corvette. By integrating these materials into the manufacturing process, Corvette engineers are able to achieve a harmonious blend of performance, handling, and aesthetic appeal.

Design Considerations and Innovations

When designing the new generation of Corvettes, engineers carefully considered various factors to ensure optimal performance, structural integrity, and occupant safety. One of the key considerations was the location of the mid-engine and its impact on safety. While the engine’s placement does not directly affect collision safety, it played a crucial role in determining the overall chassis and impact structure.

The Corvette’s body structure, including its panels and components, is designed to absorb and distribute impact energy in the event of a collision. To achieve this, a mixture of materials is utilized in the body composition of the new Corvettes, including composites, plastics, and potentially carbon fiber. These materials are carefully chosen to enhance the Corvette’s overall safety and performance.

The use of composites, such as fiberglass-based materials like sheet-molded composite (SMC), provides the Corvette with stronger and more rigid body parts. This results in improved structural integrity, reducing the risk of deformation during an accident. Composites also offer advantages in terms of weight reduction without compromising strength, further enhancing the Corvette’s agility and handling capabilities.

Additionally, lightweight plastics are incorporated into the body construction to contribute to overall weight reduction. These plastics offer flexibility in design and allow the Corvette to achieve more intricate shapes and contours. This not only enhances the aesthetic appeal of the vehicle but also contributes to its aerodynamic performance.

Furthermore, carbon fiber, known for its high strength-to-weight ratio, may be integrated into the Corvette’s body composition. Carbon fiber reinforcement can provide additional strength and rigidity to critical areas of the vehicle, further enhancing its safety and performance. This advanced material is often used in high-performance sports cars due to its exceptional properties.

Enhancing Safety with Advanced Construction Technology

Corvette construction technology has also played a significant role in improving safety. Advanced manufacturing techniques, such as robotic precision assembly and computer simulations, ensure that the Corvette’s body structure meets rigorous safety standards.

Computer-aided engineering (CAE) simulations allow for the analysis and optimization of the body structure’s performance under various crash scenarios. These simulations help engineers identify potential vulnerabilities and refine the design accordingly, ensuring that the Corvette delivers uncompromising safety.

Robotic precision assembly procedures enable the precise integration of different materials and components, resulting in consistent quality and structural integrity. This level of precision ensures that the Corvette’s body structure is capable of withstanding the various forces and stresses encountered during normal driving and in the event of a collision.

By incorporating such advanced construction technology, Corvette engineers can create a vehicle that not only exhibits exceptional performance but also provides occupants with the highest level of safety.

Innovative Design for Unforgettable Experiences

The innovative design of the new Corvettes aims to provide unforgettable driving experiences. Every aspect, including the choice of materials, is carefully considered to ensure that the Corvette delivers on its promise of performance and exhilaration.

- The use of lightweight composites and plastics contributes to the Corvette’s agility, allowing for quick acceleration and precise handling.

- The incorporation of carbon fiber, where applicable, further enhances the Corvette’s responsiveness and overall driving dynamics.

- The meticulous design and construction ensure that the Corvette’s iconic exterior lines and contours are not compromised, delivering a visually striking presence on the road.

- The combination of advanced construction materials and innovative design elements allows the new Corvettes to push the boundaries of performance, setting new standards for sports cars in the industry.

With its cutting-edge design and advanced construction technology, the new generation of Corvettes continues to impress automotive enthusiasts around the world. As technology continues to evolve, we can expect to see further innovations in Corvette construction, ensuring that this legendary sports car remains at the forefront of automotive engineering.

Conclusion

In conclusion, the new generation of Corvettes showcases a remarkable evolution in terms of construction materials. While the iconic sports car had long relied on traditional fiberglass, the incorporation of advanced composites and lightweight plastics has elevated its performance, reduced weight, and improved overall quality.

The Corvette’s body structure encompasses a combination of fiberglass-based composites, plastics, and potentially carbon fiber. This blending of materials allows for enhanced strength, rigidity, and weight reduction, key factors in delivering an exhilarating driving experience. As automotive technology continues to advance, we can anticipate further innovations and refinements in Corvette construction, ensuring that these legendary vehicles remain at the forefront of engineering excellence.

By embracing modern materials and leveraging their unique properties, Corvette designers and engineers have achieved a harmonious blend of form and function. The use of fiberglass-based composites provides durability and flexibility, while lightweight plastics contribute to weight reduction without compromising structural integrity. Additionally, the potential incorporation of carbon fiber further amplifies the Corvette’s performance capabilities, with its exceptional strength-to-weight ratio.

As the demand for high-performance sports cars continues to grow, the Corvette’s construction materials play a vital role in its enduring appeal. By combining the best of traditional and innovative materials, the new generation of Corvettes embodies the spirit of American automotive excellence and showcases the ongoing pursuit of precision engineering. With its striking design, exhilarating performance, and cutting-edge construction, the Corvette proves that it remains an icon on the road.

Source Links

- https://www.repairerdrivennews.com/2019/07/23/mid-engine-2020-corvette-stingray-incorporates-aluminum-carbon-fiber/

- https://www.corvetteblogger.com/2020/06/23/the-c8-corvette-is-loaded-with-21st-century-composite-materials/

- https://www.corvetteforum.com/forums/c8-general-discussion/4284576-will-the-c8-corvette-remain-a-fiberglass-bodied-sports-car.html